Company NewsMore >>

-

01-12 2026

How to improve quality for IXPE foaming master sheet - Sharing over ten years of experience from several senior process engineers at Ningbo Qinding

Normally, the surface of the IXPE master sheets obtained from the IXPE extruder should be smooth. However, in over water-cooled IXPE master sheets, sometimes longitudinal lines resembling ripples (usually parallel to the traction direction) appear on the surface or inside the IXPE master sheets. This phenomenon is called "water ripples" in the industry. Water ripples visually affect the appearance and lower the grade of IXPE foam products; performance-wise, they indicate uneven thickness of the IXPE foam sheet and localized degradation of physical properties (such as tensile strength and barrier properties). In short, water ripples have a significant impact on the quality of IXPE foam products. This article, drawing on over ten years of experience from several senior process engineers at Qin Ding Company, will provide a brief analysis of the causes of water ripples on IXPE master sheets and how to handle them, hoping to help our customers.

-

12-15 2025

Qin Ding Company organized a team-building activity for our employees in Xiandu, Jinyun.

From December 13th to 14th, 2025, Qin Ding Company organized a two-day team-building trip to Xiandu, Jinyun County for all employees of the Shanggao Business Unit of Qinding. The main participants in this activity were all employees of the Shanggao Business Unit (Main produts: XPE and IXPE Finished Foaming products) and some of their family members. The main purpose was as an annual employee benefit; to increase cooperation among team members; and to enhance the relationship between employees and management.

-

12-15 2025

A brief discussion on the method to ensure that IXPE mixed materials are evenly plasticized in a special extruder for IXPE foaming machine production

The structural design of the special extruder screw for IXPE foaming machine production is crucial to the plasticization uniformity of IXPE mixture materials. For example, the configuration of the threaded elements of the screw, the number and arrangement of mixing zones, etc. Multiple kneading sections and mixing elements are installed on the extruder screw dedicated for the production of IXPE foaming machines, which can realize multiple dispersion and mixing of IXPE mixture materials. But at the same time, if the IXPE mixture material is overmixed in the screw, it will easily decompose, causing the IXPE foam mother sheet to foam when it exits the extruder die (pre-foaming phenomenon). Therefore, the design of the mixing unit needs to be optimized. Our company has added innovative functions such as barrier threads, reverse elements and distributed mixing elements to the design of the extruder screw dedicated to the production of IXPE foaming machines, which can further optimize the design of the mixing unit and achieve the purpose of fully plasticizing the very good IXPE mixture without decomposition.

-

11-14 2025

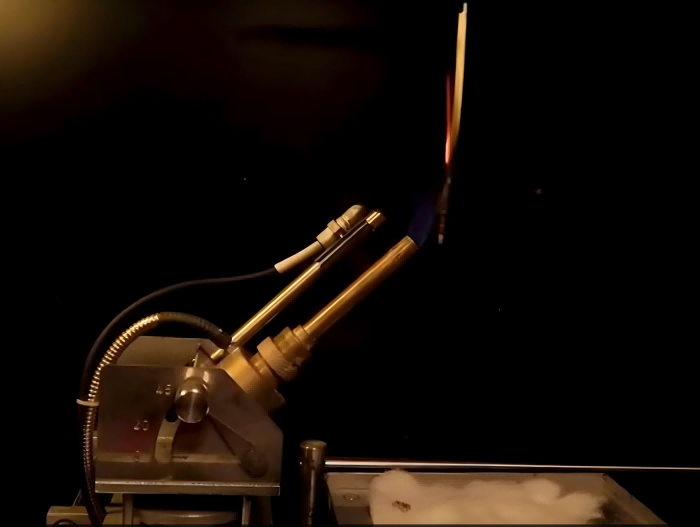

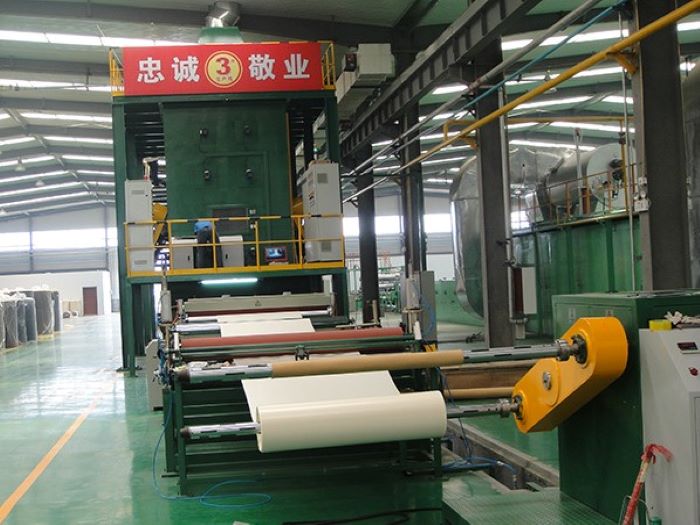

A set of XPE foaming machine-mounted structural cabinet manufactured by Qinding Company was shipped abroad

This XPE foaming machine is the QDL-1500LG model. It can produce XPE foam products with a maximum width of 1500mm. Its thickness ranges from 3 to 20mm, and its density ranges from 200 to 20kg/cbm. The XPE foaming machine is 22 meters long, features two heating sections, and is equipped with two VP300 Mikaelson gas burners. Its foaming speed can reach up to 25m/min, and its maximum XPE foam output is 250kg/h. This is our company's most mature and common XPE foaming machine.

Industry NewsMore >>

-

12-01 2025

Qinding Company visited the 2025 Ningbo Outdoor Exhibition and communicated with many XPE foam customers at the exhibition

Many Ningbo customers of Qinding Company participated in this exhibition. Our customers include outdoor camping product factories, such as XPE foam clime mats, XPE foam outdoor mats; and water sports product manufacturing factories, such as XPE foam floating mat manufacturing factories. Some of these factories have one XPE foaming machine line, and some have four XPE foaming machine lines. However, the XPE foam outdoor products they produce have a high reputation on the outdoor products platform, and they are also very popular suppliers for foreign trade companies.

-

08-12 2025

Introduction to the extrusion molding principle of XPE foam and IXPE foam motherboard and the working process of the extruder

Recently, a friend asked about selecting an IXPE extruder and wanted to know the differences between the extrusion modes of IXPE and other extruders. The following is a summary for reference by colleagues who are considering working with XPE foam or IXPE foam. XPE foam and IXPE foam master sheet extrusion molding is a process in which the mixed raw materials of XPE and IXPE are extruded through the screw and barrel of the XPE foam and IXPE foam master sheet extruder to uniformly plasticize the raw materials such as PE, and then forced through the die of the XPE foam and IXPE foam master sheet extruder to become a continuous product with a certain width and thickness.

-

10-12 2024

Application of several flame retardants in IXPE foam and XPE foam products

Halogen-free flame retardants include all halogen-free flame retardants or flame retardant systems. The main mechanism of action of halogen-free flame retardants is to form a porous carbon layer, which has the advantages of low smoke and non-toxicity. Generally, halogen-free flame retardants can be divided into inorganic flame retardants and organic flame retardants. Halogen-free flame retardant is an emerging flame retardant system in the XPE foaming and IXPE foaming industries in recent years. In the XPE foaming and IXPE foaming industries, the performance is between bromine-based flame retardants and aluminum hydride-based flame retardants. However, this flame retardant has the advantages of environmental protection, low smoke, and good flame retardant effect. In the formula system of XPE foam and IXPE foam, PE halogen-free flame retardant is commonly used, which is an organic flame retardant. Therefore, it has good compatibility with the mixture during the extrusion process of XPE foam and IXPE foam, and the formula system is also easy to adjust. Moreover, halogen-free flame retardants can meet both the EU WEEE and ROHS directives. Halogen-free flame retardants will definitely become the mainstream of XPE foam and IXPE foam flame retardant materials.

-

09-16 2024

Performance comparison of electric IXPE foaming furnace and gas IXPE foaming furnace

The above are the characteristics of IXPE foaming furnaces with three different heating methods. If you need more detailed parameters, please contact our company project manager: Mr. Henry He. Ningbo Qinding Company specializes in providing one-stop services for XPE factories and IXPE factories. Our services include: market research and planning for XPE foam and IXPE foam products; XPE foam and IXPE foam machine selection; overall factory layout; XPE foam and IXPE foam machine manufacturing; XPE foam and IXPE foam Machine installation and debugging; XPE foaming and IXPE foaming personnel training; XPE foaming and IXPE foaming technology and formula transfer; large-scale production. At the same time, we can provide special formulas and IXPP equipment and technical processes and formulas according to customer needs.