A set of XPE foaming machine-mounted structural cabinet manufactured by Qinding Company was shipped abroad

After about 4 months of busy work, Qinding Company worked together to complete the production of a set of XPE foaming machine main unit ordered by a foreign company to our company, and shipped it in container.

This equipment is the main unit of the XPE foaming furnace in the production line. This foreign customer previously had an XPE foaming furnace, but it had been performing poorly. They reported difficulty producing stable XPE foam products. Furthermore, the procurement process took a long time. To address this, they visited China in May of this year and inspected several of our domestic XPE foam product customers. After a month of research, they ultimately chose to partner with us. Since the cooling and winding auxiliary equipment in the existing XPE foaming production line was still usable, they purchased only one XPE foaming machine to replace it. Clearly, our customer is very savvy and cost-conscious.

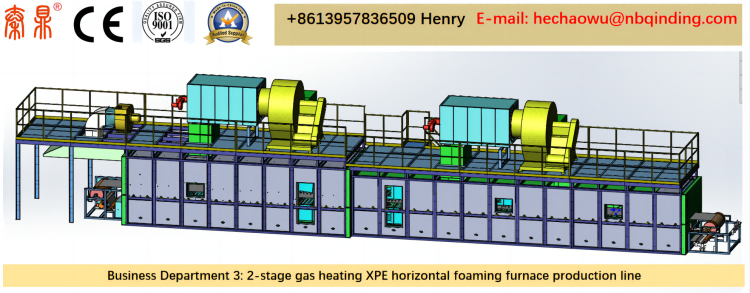

This XPE foaming machine is the QDL-1500LG model. It can produce XPE foam products with a maximum width of 1500mm. Its thickness ranges from 3 to 20mm, and its density ranges from 200 to 20kg/cbm. The XPE foaming machine is 22 meters long, features two heating sections, and is equipped with two VP300 Mikaelson gas burners. Its foaming speed can reach up to 25m/min, and its maximum XPE foam output is 250kg/h. This is our company's most mature and common XPE foaming machine.

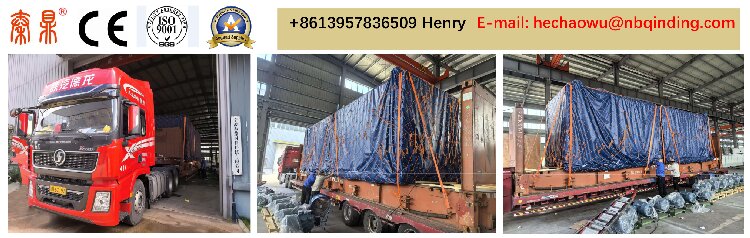

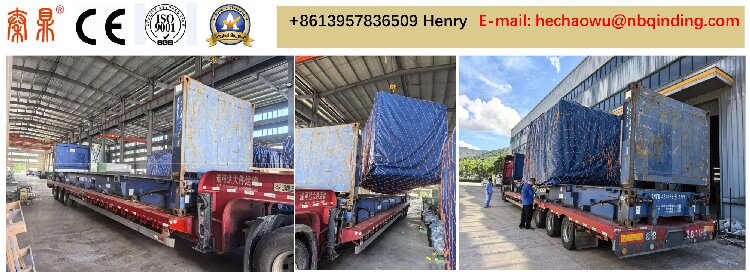

The customer, concerned with ease of installation and minimizing the impact of equipment downtime on XPE production, requested that our company manufacture a complete XPE foaming machine. The XPE foaming furnace unit is divided into four sections, connected by bolts and covered with an insulating cover. It will be shipped in a structural cabinet. Although shipping costs for structural cabinets are slightly higher than for 40HQ, upon arrival at the customer's site, assembly and trial production can be completed in as little as seven days. This model is fast, convenient, and the most economical approach across all factors. This further demonstrates our customer's shrewdness.

We wish our customers a prosperous business and great financial success.

The XPE foam machine and IXPE foaming machine division is one of the three divisions of Qin Ding Company, and it has 2 production bases. The main products are XPE foaming machine (Horizontal production line), IXPE foaming machine (Vertical production line), XPE foaming and IXPE foam sheet extruder, XPS foam product line etc. We have advanced Crosslink Foam technology and craftsmanship and a professional PE Tech Foam team, which can provide a variety of advanced project solutions for customers to choose from.