-

12-01 2025

Qinding Company visited the 2025 Ningbo Outdoor Exhibition and communicated with many XPE foam customers at the exhibition

Many Ningbo customers of Qinding Company participated in this exhibition. Our customers include outdoor camping product factories, such as XPE foam clime mats, XPE foam outdoor mats; and water sports product manufacturing factories, such as XPE foam floating mat manufacturing factories. Some of these factories have one XPE foaming machine line, and some have four XPE foaming machine lines. However, the XPE foam outdoor products they produce have a high reputation on the outdoor products platform, and they are also very popular suppliers for foreign trade companies.

-

08-12 2025

Introduction to the extrusion molding principle of XPE foam and IXPE foam motherboard and the working process of the extruder

Recently, a friend asked about selecting an IXPE extruder and wanted to know the differences between the extrusion modes of IXPE and other extruders. The following is a summary for reference by colleagues who are considering working with XPE foam or IXPE foam. XPE foam and IXPE foam master sheet extrusion molding is a process in which the mixed raw materials of XPE and IXPE are extruded through the screw and barrel of the XPE foam and IXPE foam master sheet extruder to uniformly plasticize the raw materials such as PE, and then forced through the die of the XPE foam and IXPE foam master sheet extruder to become a continuous product with a certain width and thickness.

-

10-12 2024

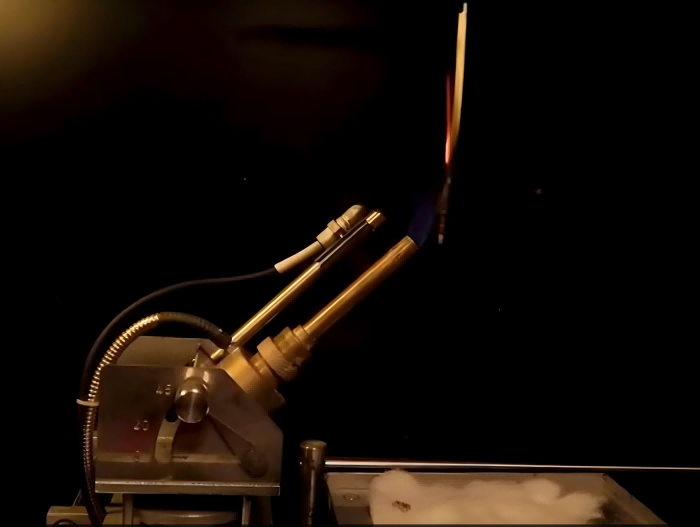

Application of several flame retardants in IXPE foam and XPE foam products

Halogen-free flame retardants include all halogen-free flame retardants or flame retardant systems. The main mechanism of action of halogen-free flame retardants is to form a porous carbon layer, which has the advantages of low smoke and non-toxicity. Generally, halogen-free flame retardants can be divided into inorganic flame retardants and organic flame retardants. Halogen-free flame retardant is an emerging flame retardant system in the XPE foaming and IXPE foaming industries in recent years. In the XPE foaming and IXPE foaming industries, the performance is between bromine-based flame retardants and aluminum hydride-based flame retardants. However, this flame retardant has the advantages of environmental protection, low smoke, and good flame retardant effect. In the formula system of XPE foam and IXPE foam, PE halogen-free flame retardant is commonly used, which is an organic flame retardant. Therefore, it has good compatibility with the mixture during the extrusion process of XPE foam and IXPE foam, and the formula system is also easy to adjust. Moreover, halogen-free flame retardants can meet both the EU WEEE and ROHS directives. Halogen-free flame retardants will definitely become the mainstream of XPE foam and IXPE foam flame retardant materials.

-

09-16 2024

Performance comparison of electric IXPE foaming furnace and gas IXPE foaming furnace

The above are the characteristics of IXPE foaming furnaces with three different heating methods. If you need more detailed parameters, please contact our company project manager: Mr. Henry He. Ningbo Qinding Company specializes in providing one-stop services for XPE factories and IXPE factories. Our services include: market research and planning for XPE foam and IXPE foam products; XPE foam and IXPE foam machine selection; overall factory layout; XPE foam and IXPE foam machine manufacturing; XPE foam and IXPE foam Machine installation and debugging; XPE foaming and IXPE foaming personnel training; XPE foaming and IXPE foaming technology and formula transfer; large-scale production. At the same time, we can provide special formulas and IXPP equipment and technical processes and formulas according to customer needs.

-

04-29 2024

Warmly congratulations on the successful holding of Chinaplus 2024 International Rubber and Plastics Exhibition.

Qin Ding Company serves the XPE/IXPE foam and Crosslink foam industries, and has 2 foaming machine manufacturing plants and 1 foaming mat manufacturing plant. The Floating mat, PE Tech Foam Coil, Crosslink Foam Floating Pad and Crosslink Foam Children Climbing Mat products of the company's Sunhigh brand have been sold on Amazon. The IXPE foam machine and XPE foam machine produced by the head office are sold at home and abroad. Qin Ding has advanced Crosslink Foam technology and craftsmanship and a professional PE Tech Foam team, which can provide a variety of advanced project solutions for customers to choose from. Welcome new and old customers to call or write to negotiate.

-

04-14 2024

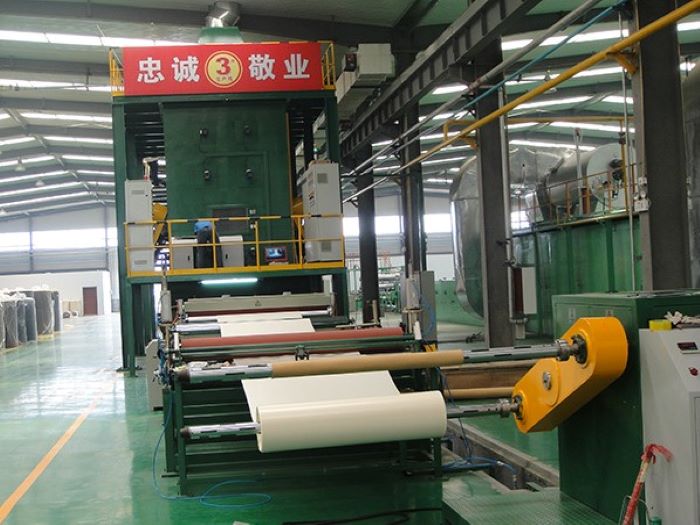

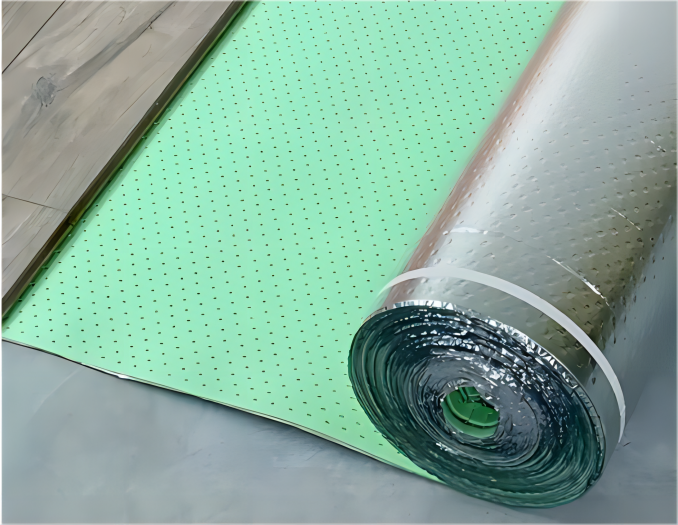

Application of IXPE foam material on SPC floor mats

Qinding Company has been deeply involved in the SPC-specific IXPE foaming machine industry for many years. The company is led by 2 senior engineers who have been in the industry for more than 20 years; more than 70 professional technical and manufacturing teams; with a professional production plant of 18,000 sqm for IXPE foaming machine line; and has provided more than 100 IXPE foaming machine production lines for the SPC-specific IXPE foaming industry at home and abroad. Recently, our company's process engineers have developed a set of effective formula for IXPE foam products specifically for the SPC industry. After large-scale production and application, this IXPE foaming formula can not only achieve effective anti-mildew and anti-bacterial properties, but also increase post-corona resistance. The glue coating effect can also extend the timeliness after corona. Our company is applying for domestic and international patents for this IXPE foaming formula, and I believe there will be good news soon.