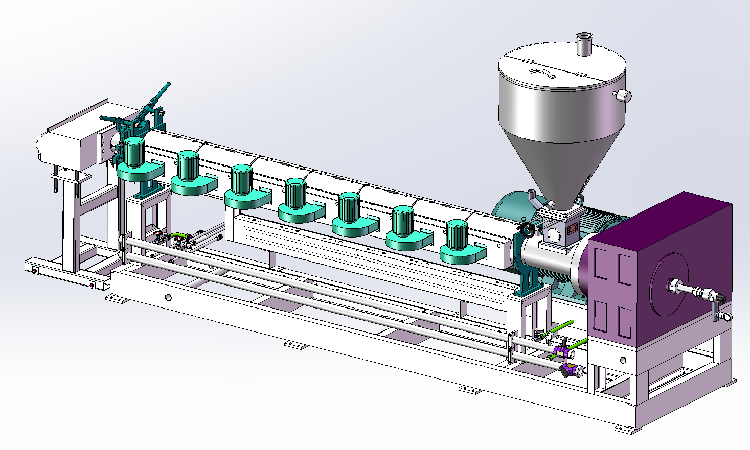

A brief discussion on the method to ensure that IXPE mixed materials are evenly plasticized in a special extruder for IXPE foaming machine production

The method of producing a special extruder for IXPE foaming machine to ensure uniform plasticization of IXPE mixed materials mainly includes the following aspects:

1. Optimize screw design:

The structural design of the special extruder screw for IXPE foaming machine production is crucial to the plasticization uniformity of IXPE mixture materials. For example, the configuration of the threaded elements of the screw, the number and arrangement of mixing zones, etc. Multiple kneading sections and mixing elements are installed on the extruder screw dedicated for the production of IXPE foaming machines, which can realize multiple dispersion and mixing of IXPE mixture materials. But at the same time, if the IXPE mixture material is overmixed in the screw, it will easily decompose, causing the IXPE foam mother sheet to foam when it exits the extruder die (pre-foaming phenomenon). Therefore, the design of the mixing unit needs to be optimized. Our company has added innovative functions such as barrier threads, reverse elements and distributed mixing elements to the design of the extruder screw dedicated to the production of IXPE foaming machines, which can further optimize the design of the mixing unit and achieve the purpose of fully plasticizing the very good IXPE mixture without decomposition.

2. Setting of process parameters:

(1) Temperature distribution design: Reasonable temperature control is the key to ensuring uniform plasticization of IXPE mixed materials. In each section of the special extruder for IXPE foaming machine production, the temperature needs to be accurately controlled. For example, the temperature of the homogenization section is usually slightly lower than the melting section, but the die temperature needs to be slightly higher than the temperature of the homogenization section to ensure the fluidity and density of the material.

(2) Precise temperature control: IXPE mixed materials belong to a low-temperature extrusion process and have poor thermal stability. Therefore, in the design of the extruder dedicated to the IXPE foaming machine, we have incorporated the extruder's ability to accurately control temperature and rapidly cool. Significantly reduces the pre-foaming phenomenon of IXPE mixed materials in the extruder.

(3) Adjust the appropriate screw speed and feed rate: In the design of the extruder dedicated to the IXPE foaming machine, we systematically changed and analyzed the impact of screw speed, feed rate and other factors on the IXPE mixture material through statistical methods such as design of experiments (DOE); optimizing the residence time distribution (RTD) improved the uniform plasticization speed of the IXPE mixture material; and analyzed the flow behavior in the extruder dedicated to the IXPE foaming machine (including laminar and turbulent flow states, etc.). We actually apply the data from these tests and analysis to the production process of IXPE Foaming master sheet. Different IXPE mixture materials correspond to different screw speeds and feed speeds. It greatly improves the production efficiency of IXPE Foaming master sheet and reduces the quality of IXPE foaming master sheet.

3. IXPE material selection and formula setting

First of all, ensure that the selected material properties are suitable and try to choose materials with good thermal stability, which can reduce the requirements on the extruder heating and cooling system. At the same time, the particle size and shape of the material are analyzed to ensure that the IXPE mixed material can enter the barrel evenly and smoothly and be effectively mixed without stratification. In formula design, try to reduce the amount of auxiliary raw materials that affect the thermal stability of IXPE mixture materials.

4. Attempts at new pre-mixing processing methods for IXPE mixed materials:

Before entering the special extruder of IXPE foaming machine, the raw materials of the IXPE mixture formula are premixed. Premixing includes hot mixing and cold mixing. The hot mixing process includes diffusion, convection and shearing to achieve uniform dispersion of IXPE mixed material components. After hot mixing and cold mixing, a uniform and stable dry-mixed IXPE formula material can be formed, which improves the pre-dispersion effect of the material, thereby improving the plasticizing effect of the IXPE mixture material in the extruder dedicated to the IXPE foaming machine. Note that when selecting mixing equipment, it is necessary to select appropriate mixing equipment according to the characteristics of IXPE mixed materials. For example, for materials with larger particles or irregular shapes, a twin-screw extruder with a larger feed opening and stronger crushing capacity needs to be selected as the premixing equipment.