A set of Electric heating IXPE foam machine production line manufactured by Qinding Company was loaded into containers and shipped abroad

Recently, a set of electrically heated IXPE foaming production machine (excluding accelerator) manufactured by Qindong Company has completed debugging and packaging at our factory and was shipped overseas.

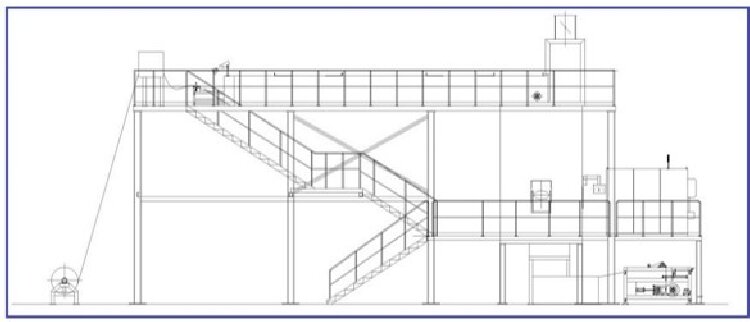

This IXPE electric foaming machine production line adopts the design concept of horizontal preheating section+vertical foaming. The length of the horizontal preheating section is 10m, the height of the vertical foaming section is 4m, the design line speed is 9m/min (the foaming product has a density of 33kg/cbm (foaming ratio of 30 times), a thickness of 3mm, and a width of 1500mm), and the output is 80kg/h

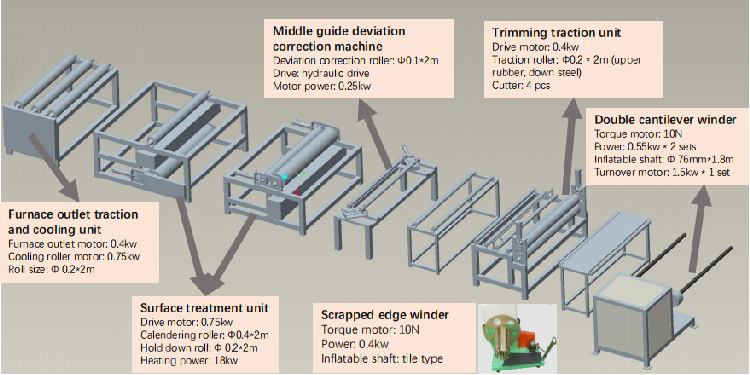

This IXPE foaming production line still includes the following components: unwinding machine for IXPE foaming machine line, special feeder for IXPE foaming machine, horizontal foaming furnace of IXPE foam machine, vertical foaming furnace of IXPE foam machine, vacuum adsorption expansion mechanism for IXPE foaming machine, furnace mouth traction machine and five-roller cooling machine, A complete IXPE foaming unit such as a special sheet tractor for a foaming machine, a special winding machine for a foaming machine, etc.

In order to facilitate better and faster installation at our IXPE foreign customer, this IXPE foaming machine production line adopts a fully modular design. Moreover, the design size of the IXPE foaming machine line, both the IXPE foaming main body and the auxiliary machine, are suitable for 40HQ container shipments, which greatly reduces the usage fees and sea freight of non-standard containers for customers. This IXPE foaming machine production line uses a total of 6 containers.

It is expected that this set of IXPE foaming machine production line will arrive at our overseas customer site after 50 days of sea travel. I wish our customers every success and a prosperous business!