-

07-24 2021

Three methods of cross-linking and foaming of polyethylene under normal pressure

The molding methods of polyethylene foam include extrusion, injection, molding, orientation and other methods. Among them, the extrusion method is divided into direct extrusion foaming and cross-linking foaming after extrusion. After extrusion, cross-linked foaming can be divided into chemical cross-linked foaming, physical cross-linked foaming and mixed cross-linked foaming.

-

07-09 2021

IXPE foam material has broad development prospects

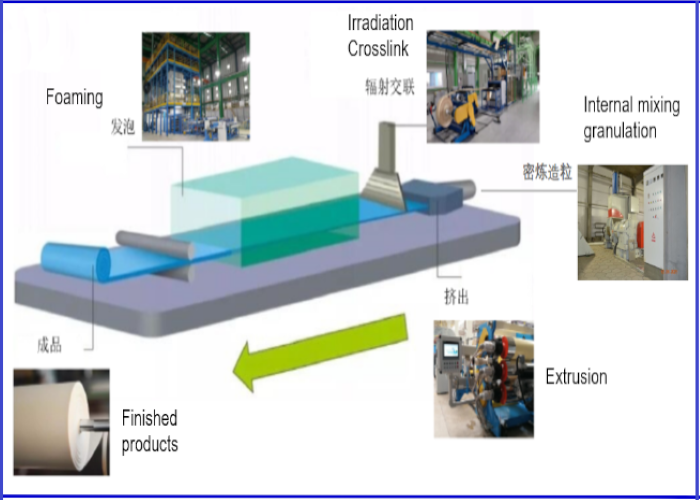

The full name of IXPE foam material is electron radiation cross-linked polyethylene foam material. It is based on LDPE (low-density high-pressure polyethylene), ADC foaming agent and color masterbatch as the main raw materials, with other auxiliary materials, after granulation and extrusion molding processes, the use of high-energy electron beams generated by industrial electron accelerators to extrude The formed mother film is irradiated to build a chain bridge between the molecules, and then foamed at a high temperature to form an independent closed-cell foam material. Finally, the material can be processed into the final foam product after punching, printing, thickening and other back-end processing procedures.

-

05-17 2021

Application examples of IXPE foam products in the tape sealing industry

IXPE foam products are widely used in all walks of life due to their superior comprehensive performance. Among them, there are many applications in the tape sealing industry.

-

05-12 2021

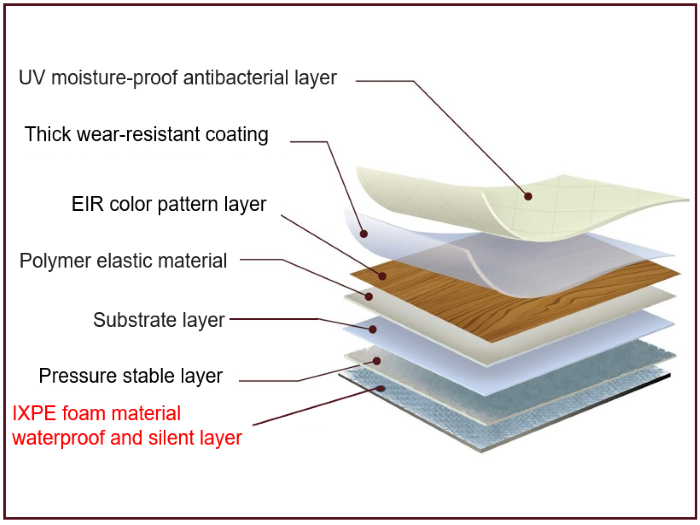

Application details of IXPE floor mats

IXPE floor mat is a silent mat. It is a foamed film made of high-pressure polyethylene (LDPE), cross-linked by electron irradiation, and foamed with an IXPE foaming machine. Ultra-fine foam provides cushioning and shock absorption. The composite aluminized film can play a role in moisture-proof. Installed under the floor, not only can absorb vibration and sound insulation, but also keep warm for floor heating. If special ingredients are added when making IXPE foam, IXPE foaming material with antibacterial, mildew, and flame retardant functions can also be made.

-

05-10 2021

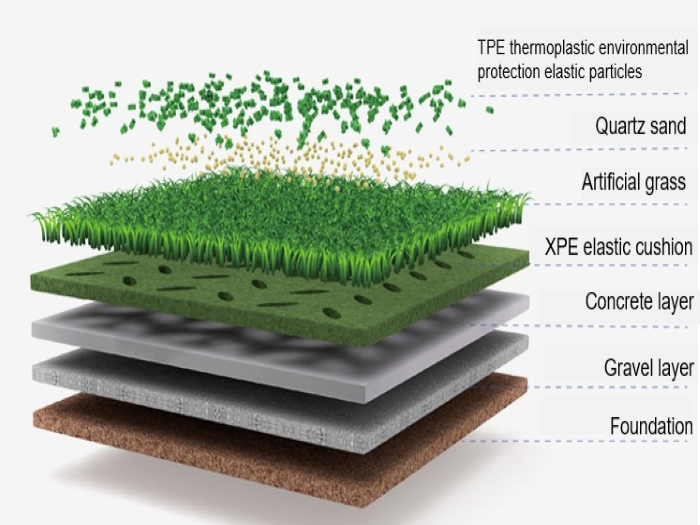

Application details of XPE foam and IXPE foam material in lawn mats

XPE foaming machine (main machine including pelletizing unit, master chip extruding unit, XPE foaming furnace unit) is used to produce XPE coils. The thickness of this kind of coil is generally 8~12mm, the width is mostly 1.5m, the length of a single coil is generally 72m, and the XPE coil has a magnification of 30~35 times. It requires fine foam cells and good resilience. The colors are mainly green XPE foam and milky white XPE foam, some of them will use natural XPE foam, and black XPE foam will be used less.

-

05-07 2021

IXPE foamed coil production process introduction

The production of IXPE foaming products is a sophisticated and complex process. Every link is indispensable and very important. If a perfect IXPE foaming product is to be produced, process control is very important. Qin Ding is a professional IXPE foaming machine provider. It has more than 10 years of first-line production experience and has accumulated rich experience. It can provide customers with unique help from raw material selection, site planning, equipment selection, formula and technology, and personnel training.