XPE IXPE foam machine line IXPE for SPC Foaming machine XLPE virtical foaming furnace

SPC dedicated fully automatic IXPE foaming machine line commissioning log

Qinding Company provided 4 sets of SPC-specific IXPE foaming machine lines at one time to the overseas production base of a domestic large multinational SPC production enterprise. According to customer requirements, the most advanced technology and production process were introduced in the design of the IXPE foaming machine production line; at the same time, many automation systems were added to the entire IXPE foaming machine production line. This set of IXPE foaming machine production line greatly saves labor costs, reduces waste and possible human errors; and introduces advanced catalytic combustion heat exchange system, which is very energy-saving.

·Automatic weighing and automatic feeding before kneading machine:

·Automatic weighing and automatic feeding before extruder;

·Automatic screen changing of extruder;

·Most worth mentioning is that the foaming furnace adopts a catalytic combustion heat recovery system, which greatly and effectively reduces the consumption of gas.

Recently, Qinding Company's commissioning engineers spent one month commissioning and delivering the four SPC-specific IXPE foaming production lines:

1. Manufacturing IXPE foaming masterbatch

The granulation system equipped in this IXPE foaming machine production line has an automatic feeding function. First, Qinding's commissioning engineer inputs the IXPE foaming granulation formula into the automatic feeder; then manufactures IXPE foaming masterbatch with different functions according to the formula, such as foaming masterbatch, additive masterbatch, special function masterbatch, etc.

2. Extrusion of IXPE foaming mother sheet

The extruder equipped in this IXPE foaming machine production line has two innovative features: automatic feeding before the extruder and automatic screen change before the Y-type mold. First, according to the requirements of the IXPE foaming mother sheet, enter the IXPE foaming mother sheet formula into the automatic feeder. The automatic feeder automatically weighs according to the formula of the IXPE foaming mother sheet and feeds the weighed mixed material into the hopper of the extruder; then the extruder extrude the IXPE foaming mother sheet according to the preset process route and rewinds it.

3. Irradiate the extruded IXPE foam mother sheet

According to the specifications of the IXPE foam mother sheet, select the appropriate number of beam winding layers and the appropriate energy; determine the beam current of the electron beam according to the process book; place the IXPE foam mother sheet on the unwinder; after starting the accelerator and entering the normal working procedure, connect the IXPE foam mother sheet to the lead sheet and enter the accelerator to allow the IXPE foam mother sheet to be irradiated to achieve the appropriate cross-linking degree; finally, rewind the irradiated IXPE foam mother sheet.

4. Foaming of irradiated IXPE foaming mother sheets

The foaming furnace of the IXPE foaming line equipped this time is a gas-fired vertical IXPE foaming furnace. The furnace type adopts a combination of horizontal preheating furnace section + vertical foaming furnace section; the heating system introduces an advanced catalytic combustion heat recovery system, which continuously and stably transports heat into the foaming furnace through fans and pipes for cyclic heating.

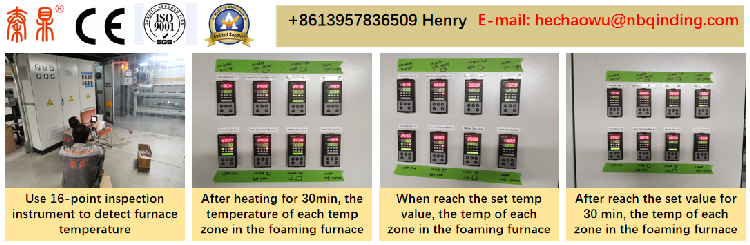

Before running the IXPE foaming furnace with materials, our commissioning engineers used a 16-point temperature recorder to perform 16-point temperature detection on the horizontal furnace section of the empty IXPE foaming furnace and the upper, middle and lower temperature zones of the vertical furnace. Through the detection, it can be seen that the temperature uniformity of each independent temperature zone in the IXPE foaming furnace is very good, whether in the heating stage or the insulation stage.

After completing the temperature test, Qinding's engineers placed the irradiated IXPE mother sheet on the foaming furnace feeder for foaming. At the preset temperature, the foaming was perfect.

The complete foaming furnace operation video is as follows:

We wish our customers prosperous business and great wealth!